Microgrids are a hot topic across the energy industry. New and innovative technologies are advancing energy resiliency. Zondits spoke with Andrew Yip, Director of Business Development for Bosch, to learn more about their DC Microgrid platform and how this technology is redefining energy generation.

What differentiates a DC microgrid from an AC microgrid?

Today’s building loads are operated by power electronics devices. These end-use devices (such as plug loads, LED lights, electric vehicle (EV) chargers, and variable speed drives) need DC power for their operation. All of these devices typically have inefficient rectifiers that convert AC utility power to DC for their use. Similarly, on-site distributed generation devices (such as solar photovoltaic and energy storage) produce DC power. The energy from these systems must be converted into AC using an inverter to interconnect with the existing AC utility grid. These inverters also have efficiency losses.

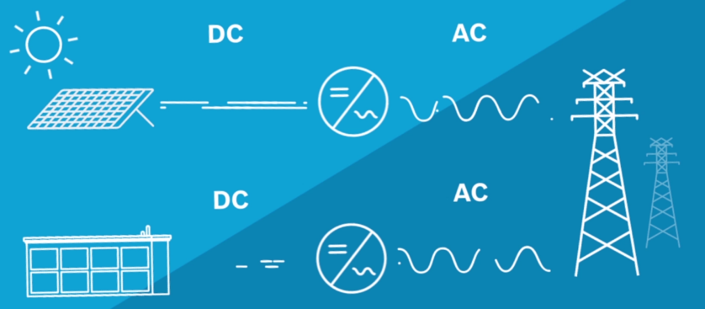

In an AC microgrid architecture, the on-site distributed generation systems and building loads are not directly connected during normal operation. This system goes through a DC-AC-DC conversion, where the utility grid is the AC point of interconnection, as shown in Figure 1:

In addition, the requirements for enabling an AC microgrid to island from the utility grid and provide resiliency to the facility are not simple or cheap. Costly interconnection studies must be done and expensive transfer switches must be installed. The system must also be synced to the utility grid for safety, causing a momentary outage.

In a DC microgrid architecture these issues are virtually eliminated with increasing efficiency and reliability. Most of the power conversion devices are removed because the on-site distributed generation devices are directly connected to building loads on a DC distribution network, increasing the use of the on-site energy by an average of 7%-10% per year, as shown in Figure 2.

A DC microgrid is capable of islanding from the utility grid without complex switching devices. In a grid outage, the on-site distributed generation systems continue to power the building loads without any interruption, and it does not need to sync with the AC grid when returning to grid service. This ultimately provides higher power quality to customers and the utility compared to an AC microgrid.

Is there a maximum rated value facility load under which a DC microgrid is less expensive to install and operate than an AC microgrid? (Or: Is there an ideal connected load range for DC?)

A DC microgrid can support any size building load and be cost-competitive with AC microgrids. In a DC microgrid architecture, the most ideal and cost-effective on-site distributed generation system is sized to ensure that the majority of the energy is consumed by the loads directly connected to it. This ensures that nearly 100% of that DC energy is consumed by the DC building loads. However, it is still capable of cost-effectively exporting excess on-site energy if needed to support various tariffs and utility programs that provide customers with credits on their energy bill.

What are the best applications (loads) for DC microgrids?

In Bosch’s DC microgrid platform, static loads such as lighting, HVAC, EV charging, and other motor loads are the best fit. These are generally the largest energy users within commercial facilities. Bosch operates the DC microgrid on a nominal 380V DC network, which allows the on-site energy such as PV arrays to directly connect at this voltage level without the need to significantly step down the voltage to drive these loads.

How can the commercially available end-use equipment be connected in a DC microgrid? Are there equipment limitations?

Today’s commercially available end-use equipment would need modification in order for it to be connected in a DC microgrid. These devices operate on DC; however, they have power conversion devices that convert the utility AC power to DC for its operation. These power conversion devices are no longer needed and would be removed when connected in a DC microgrid. In some instances a DC/DC converter may be needed to allow the DC input voltage to support the voltage needed to power the device efficiently. As the market and industry for DC systems develop and mature, it is expected that commercially available end-use equipment will be DC and thus will connect to a DC microgrid without modification.

How do the building and fire codes in force in the US accommodate or encumber the installation of DC distribution equipment?

DC microgrids currently meet all existing building and fire codes. In fact, the recently approved 2017 National Electric Code developed a new Article (Article 712) for DC Microgrids. One cost-effective value of DC microgrids operating on 380Vdc is that existing AC wiring infrastructure in a building can be re-used to run DC power. No re-wiring is necessary for a building retrofit application as the national electric code allows the re-use of wiring as long as the wires are labeled accordingly. 380 Vdc microgrids also lower the risk of electrical shock or fire compared to 208-277Vac systems. This is accomplished by implementing a high resistance midpoint ground (HRMG) configuration in the system. During normal operation this configuration never actually allows the line-to-ground bus voltages to exceed +200Vdc and -200Vdc, therefore cutting the DC bus line voltages in half. During a fault situation (line to ground), the midpoint grounding resistors limit the amount of current that can flow to the ground through the faulting device to IEC Zone II safety levels.

As additional DC microgrids are installed in the field, more knowledge will be achieved by the industry as well as fire and building code officials. This will help in streamlining the field inspection process, keeping inspection cost down. There is also an opportunity to make further refinements to building codes that will make DC systems even more efficient and cost-effective. Existing codes were initially written for AC systems, and with the growth of DC systems the codes will need to adjust to ensure that DC systems are also installed safely and in a cost-effective manner.

How do the federal and state governments in US support the DC microgrid installations?

Federal and state governments are excited about DC microgrids and their potential to support mission-critical facilities. They see the value of developing an integrated energy system with high reliability at the lowest possible cost with the ability to cost-effectively add resiliency. Bosch has installed a DC microgrid for the Department of Defense at Fort Bragg, NC, that has been in operation for over three years. There have been no reported issues and the microgrid has provided benefits to the facility.

What are the barriers that would slow down DC microgrid deployment?

Inadequate education in the industry is currently a barrier that can slow down DC microgrid deployment. There needs to be more awareness and education to end-use customers that DC microgrids are market-ready and understanding the benefits and their ability to be more cost-effective than comparable AC systems. There is also a need to raise awareness with other critical stakeholders, such as maintenance and facility staff, about the advantages of operating devices in DC and the reduction in equipment replacement costs. Finally, there is very little awareness at the installer and inspector level that DC microgrids meet current building and fire codes and can be installed without additional code or certification requirements.

Bosch Building Grid Technologies is part of the North American subsidiary of the Bosch Group, which is a leading global supplier of technology and services. The Building Grid Technologies group is focused on deploying direct current (DC) microgrid systems that take a holistic approach in connecting on-site distributed generation sources to major energy loads in a commercial or industrial building on a 380 VDC network. The Bosch Group employs approximately 375,000 associates worldwide and generated sales of $78.3 billion in 2015. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. The Bosch Group comprises of Robert Bosch GmbH and its roughly 440 subsidiaries along with the sales and service partners are represented in roughly 150 countries. This worldwide development, manufacturing and sales network is the foundation for further growth.